The foundation stitch is another way in which you can begin your crochet project. All crochet projects start off by doing the chain stitch (ch) so that you have a base in order to complete the next row of stitches according to your pattern directions.

Doing a foundation stitch is a little different than just crocheting a long row of chain stitches. It is basically a way of doing the single crochet (sc) to form your first row of stitches. One of the main reasons I will begin a project using the foundation stitch is that it doesn’t seem to end up as tight as a long string of regular chain stitches. I find that after I have crochet for just a couple of rows, my beginning chain row actually is a little tighter than my other rows, even when I am consciously making an effort to keep my chain stitches loose.

The foundation stitch is great for any project but I find it is especially great for afghan patterns when your directions call for you to crochet 100 or more chain stitches. It is easy to count your stitches and keeps an even tension with your other rows of crochet stitches.

You just crochet the foundation stitch and count it like a regular chain stitch and when you have reached the number of stitches necessary for your project, just add a regular chain stitch (ch) for turning purposes. Then proceed with your next row according to your pattern directions.

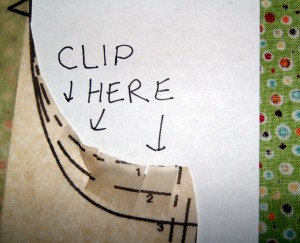

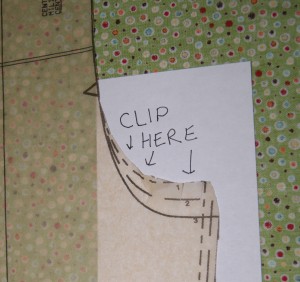

To make a foundation chain, begin by making 2 chain stitches (ch), then insert your hook under the top 2 loops of the 2nd chain, yarn over and pull the loop through (2 loops on your hook), yarn over again and pull the loop through ONLY the top loop on your hook (still 2 loops on your hook), then yarn over and pulling through both loops on your hook (now only 1 loop left on hook). You have just completed one (1) foundation stitch.

Now, you will insert your hook through both strands of the foundation stitch that you just completed, yarn over and pull through those two strands only (2 single loops on hook), yarn over again pulling only through the top loop on hook (2 loops still on hook), yarn over and pull through both of those loops (1 loop remaining on hook). Another stitch completed. Continue in this fashion until you have made all the necessary chain stitches required for your pattern. Again, be sure to end your row making one or more regular chain stitches for turning purposes.

- TIP: Your pattern directions should tell you how many turning chains you need to complete to have the required height for the new row of stitches. For example, you will need (1) chain stitch, turn and continue with a single crochet; will need (2) turning chain stitches to continue with half-double crochet; need (3) turning chain stitches for double crochet; (4) turning chain stitches for triple crochet, etc.

Have fun with the foundation stitch because you will discover what a great stitch it is!! Be sure to click on photos to zoom in for larger image.

HAPPY CREATING!!

Disclaimer: This post contains affiliate links – “small commission earned”